Ball Joints

Ball joints are spherical bearings connecting control arms at steering knuckles. As a wheel moves up and down, the suspension pivots through ball joints, allowing the wheel to move independently from the chassis.

MACPHERSON RIDE CHASSIS IS YOUR GO-TO FOR TRUSTED PERFORMANCE FOR ALL POPULAR TRUCKS & VEHICLES

OPTIMAL PERFORMANCE

Setting the industry benchmark with quality components, MacPherson ball joints are designed with improved dust boot designs and materials for superior performance.

FASTER INSTALLATION

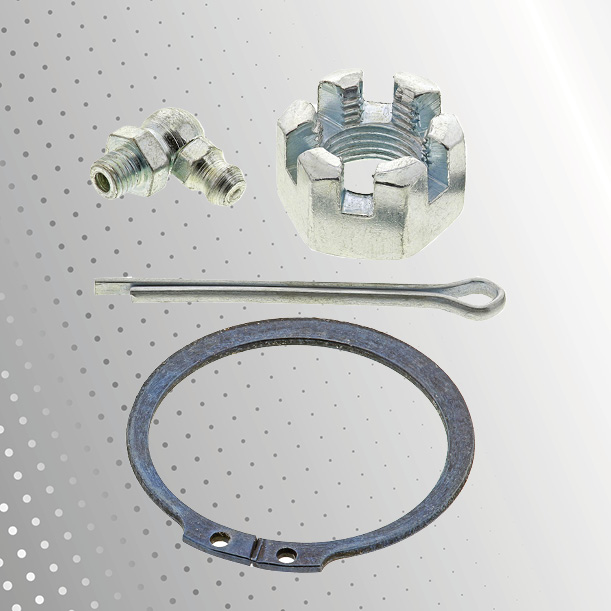

Save time with installation hardware included in the box.

PERFORMANCE BACKED BY DESIGN EXCELLENCE

Meet or exceeds Original Equipment specifications for fit, form and function.

ULTRA-GUARD™ CORROSION COATING

Prevent harmful rust buildup and increase part longevity with protective anti-corrosion surface treatment.

MACPHERSON TRUCK APPLICATION

Experience maximum performance from ball joints upgraded to excel in heavy-duty operating environments.

MACPHERSON CAR APPLICATION

Get more service life out of tough, durable ball joints designed to stand up to wear and tear.

BOOTSTALLER

Speed up installation and place ball joint perfectly with this time-saving tool in the box.

VERY BEST IN SUSPENSION PARTS, RESTORING ORIGINAL EQUIPMENT PERFORMANCE, HANDLING & RIDE

Ball joints are spherical bearings connecting control arms to steering knuckles. As a wheel moves up and down, the suspension pivots through ball joints, allowing the wheel to move independently from the chassis.

Depending on the suspension system (solid axle, double wishbone, multi-link or MacPherson strut), ball joints may be located on front upper and/or lower control arms and steering knuckles, as well as in some rear suspension systems.

BALL JOINT DESIGNS

Press-In – The ball joint is tightly pressed into the control arm, supplemented by a circlip.

Bolt-On – OEM ball joints may be riveted to the chassis. An aftermarket bolt-on design has a mounting flange that bolts onto the control arm or steering knuckle.

Unitized – Aluminum OEM control arms often integrate the ball joint into the assembly. This may require replacing the entire assembly.

Bad/Worn Ball Joint Symptoms

• Clunking noises from the front suspension

• Excessive vibration from the vehicle’s front end

• Steering wandering left or right

• Uneven tire wear

• Inability to align the steering and suspension system

Checking for Bad/Worn Ball Joints

• Uneven wear spots on the tires, or the front of the wheels pointing out, may indicate worn ball joints. If tire wear is equal on both sides, it’s probably under-inflated tires.

• Rock the tire on its wheel axis by placing the vehicle on jack stands and grasping the tire’s top and bottom to rock it in and out. Good ball joints should have little to no play. Noise and play from the top indicate an upper ball joint problem, and from the bottom indicates a lower ball joint problem.

• Remove the wheel and inspect the upper and lower ball joints for signs of rust, dust boot damage or perforation, leaking grease or any other potential problem.

• Place a pry bar between the lower control arm and the steering knuckle (the two components connected by the ball joint) and attempt to pry them apart. Excessive play, movement and/or clicking sounds are signs the ball joints are too loose and need replacing.